Subsolador Power UM 132

CALIDAD UNVERFERTH USA

Los subsoladores Unverferth contribuyen a disminuir la compactación, mejorar las condiciones de porosidad e infiltración, con una mínima alteración de la superficie del suelo.

Fabricado en USA, el subsolador Power UM 132 con vástagos (brazos) automáticos, con el sistema patentado por Unverferth, se desplaza hacia atrás y hacia arriba desde un único punto de pivote para un desempeño eficiente en suelos duros y rocosos; además, su brazo de tiro más amplio y resistente, le da mayor estabilidad y fuerza.

-

Máximo Desarrollo Radicular De Las Plantas

La compactación, además de ser la mayor causante de erosión superficial, reduce los rendimientos al impedir que las raíces se desarrollen libremente, por todo el suelo, en busca de agua y nutrientes.Los subsoladores Unverferth contribuyen a disminuir la compactación, mejorando las condiciones de infiltración y la porosidad, con una mínima alteración de la superficie del suelo, preparándolo para el mejor desarrollo radicular de las plantas, evitando pérdidas de carbono almacenado y favoreciendo a la supervivencia de microorganismos.

-

Vástagos (Brazos)

Los vástagos están probados en campo con una presión de disparo de 2.700kg para una profundidad de trabajo consistente.

- El diseño de 19mm de ancho y alta resistencia, proporciona la máxima fuerza y la mínima alteración del suelo, rompiendo la capa compactada hasta 50cm de profundidad.

- Posee una punta de centro elevado de 45 mm con diseño cónico para una menor ruptura del suelo a mayores velocidades.

- Las barras de desgaste invertibles, fundidas, y tratadas térmicamente, aumentan la durabilidad del vástago. Más estrechas en el centro para cortar fácilmente el suelo y aliviar la compactación más profunda con un mínimo revolvimiento de la superficie.

- OPCIONAL: Único con protector de puntas resistente a la abrasión, aumenta la vida útil del vástago.

Discos de corte

- Dos opciones de disco: ondulados de 20″ o planos de 24″ para adaptarse a las condiciones del suelo.

- 680kg de presión en el suelo corta fácilmente el residuo más pesado.

- Los discos se colocan directamente delante de los vástagos para optimizar el flujo de residuos.

- Las abrazaderas fundidas para el montaje de los discos de corte tienen una sujeción bidireccional para mantener el disco en línea con el vástago para una alteración mínima del suelo.

- Dos rodamientos de rodillos cónicos de alta resistencia protegidos con sellos de triple labio, juntas O-rings y tapas de cubo encastradas con anillos de retención para un uso a largo plazo y sin problemas.

Chasis

El chasis de construcción rígida, con el peso adecuado para el trabajo de descompactación, provee excelente estabilidad y mantenimiento de la profundidad en todos los tipos de suelo.

- Doble marco, construcción totalmente soldada con una barra trasera de 6“x 6”.

- Excepcional espacio debajo del chasis de 38″ para mejorar el flujo de residuos.

- El diseño único del implemento permite el posicionamiento del vástago en espaciamientos de surcos variables de 20″ a 40″.

- Ancho de trabajo hasta 25% mayor a la competencia.

- Disponible en modelos de 4 a 9 vástagos con espacios de 30″.

-

Rolling Harrow

Rodillo metálico para el acondicionamiento perfecto de la cobertura del suelo, con presión descendente ajustable y cuchillas angulares ranuradas, corta y distribuye uniformemente los residuos, incluso los más agresivos, proveyendo una cobertura homogénea para una mejor siembra posterior y una emergencia más uniforme de las plantas

-

Único Con Alas De Descompactación

Las alas descompactadoras, exclusivamente desarrolladas por Unverferth para romper capas subterráneas, posibilitan un mayor espaciamiento entre surcos, lo que aumenta el ancho de trabajo y las hectáreas por hora, con la misma cantidad de vástagos, potencia y consumo de combustible del tractor. sistema también permite realizar la calibración sin salir de la cabina, y guarda todos los datos de siembra.

-

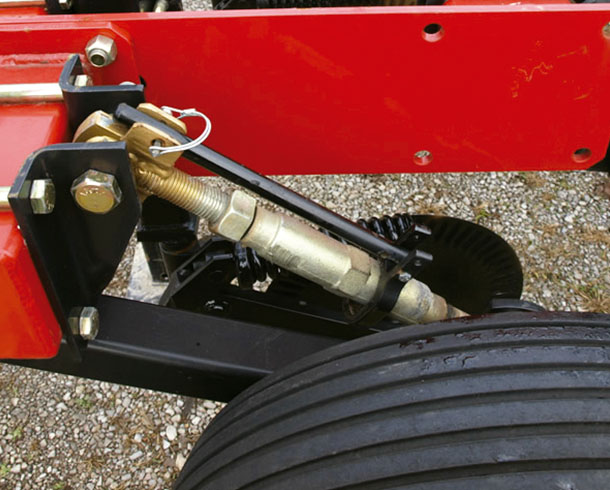

Rueda estabilizadora

Excelente control de profundidad , sistema de ruedas estabilizadoras fácilmente ajustable sin esfuerzo extra o herramientas.

- Ajuste sin herramientas para una mayor versatilidad de campo a campo.

- Los modelos de estructura rígida están equipados con neumáticos nuevos de 8 capas de 7,60 x 15; los modelos de 6-10 vástagos plegables tienen neumáticos de 8 capas de 9,5L x 15, y los modelos de 12 y 16 surcos tienen neumáticos de 10 capas de 12,5x15.