PLANTADORA TEMPO L

PRECISIÓN, TECNOLOGÍA Y VELOCIDAD

Tempo L es una plantadora de alta velocidad de Väderstad

Diseñada para ofrecer una precisión inigualable sin importar las condiciones del terreno; incluso a velocidades de hasta 20 km/h garantiza una emergencia uniforme de las semillas.

Características Principales

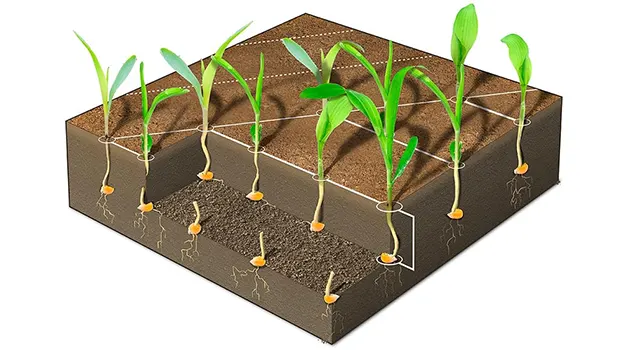

•Control Total de la Semilla: gracias a la tecnología PowerShoot, la semilla es impulsada con precisión hasta el suelo, eliminando los efectos de la gravedad, vibraciones y pendientes.

•Precisión Tridimensional: asegura un espaciamiento exacto entre semillas, profundidad uniforme y cierre individual de líneas de semillas, fertilizantes y micro granulados.

•Control de Profundidad Perfecto: su sistema hidráulico distribuye uniformemente el peso de la máquina, aplicando hasta 325 kg de presión por línea, adaptándose a las irregularidades del terreno.

•Óptimo Contacto Semilla-Suelo: sus ruedas de presión aseguran que cada semilla sea presionada y quede colocada correctamente en el suelo, promoviendo una germinación rápida y uniforme.

Sistema de Transporte Eficiente: la Tempo L cuenta con un sistema de transporte integrado que facilita su traslado entre campos o por carretera, ahorrando tiempo y aumentando la seguridad.

E-Control – Control Inteligente en Tiempo Real: mediante un iPad, el operador puede controlar y monitorear toda la plantadora en tiempo real: dosis de siembra, corte por secciones, funciones hidráulicas, presión por línea y más. El sistema también permite realizar la calibración sin salir de la cabina, y guarda todos los datos de siembra.

Beneficios Operativos

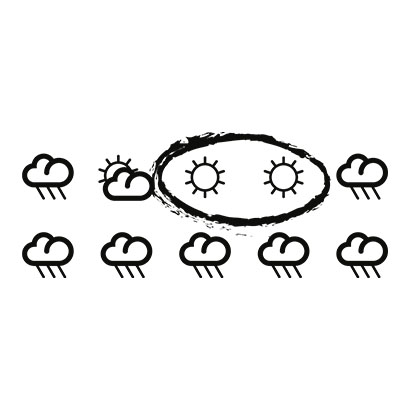

Ventana Óptima de Siembra:

Su velocidad de operación permite realizar la siembra en el momento ideal, incluso adelantarse a condiciones climáticas adversas.

Alta Capacidad de Trabajo:

Permite sembrar grandes superficies en menos tiempo, aumentando la eficiencia.

Menor Uso de Recursos:

La alta velocidad de siembra permite que una plantadora más compacta cubra la misma área que una más grande, reduciendo la necesidad de potencia del tractor y aumentando la eficiencia en el campo.

MODELOS DISPONIBLES

Tempo L

Ideal para quienes buscan versatilidad, alta velocidad e integración de fertilizante con control avanzado.

• Permite siembras escalonadas diversas, ej: Maíz y Brachiaria, líneas 1x1 o 2x1.

• Desde 10 hasta 24 líneas a 45cm-50cm, modificables.

Tempo L Central Fill

La mejor opción para grandes áreas, combinando máxima autonomía con rapidez y facilidad en el transporte.

• Caja central de 7200L para semilla y fertilizante.

• Modelos de 20 líneas a 50cm y 22,24,26 líneas a 45cm-50cm, modificables.

Tempo L Central Seed

Perfecta para quienes desean eficiencia en el reabastecimiento, con distribución centralizada de semillas y automatización por línea.

• Caja central de semillas, desde 12 a 26 líneas a 45 y 50 cm.

Qué dicen nuestros clientes:

"Con la Tempo L puedo sembrar más rápido, cubriendo más hectáreas en menos tiempo y con una precisión impresionante. Está equipada con la mejor tecnología de siembra del mercado, lo que me permite ahorrar insumos, tiempo y dinero"

"Llevo un año manejando la Tempo L en unas 2.000 hectáreas y hasta ahora, ha funcionado muy bien. Lo que más destaco es la velocidad de trabajo y la calidad de la siembra. Planta rápido y de forma muy precisa. Los resultados han sido muy buenos."